16 mins read

Key Steps For Successful Procurement Management In Construction

- Procurement Management in Construction

- Types Of Procurement In Construction Management

- Who Is Responsible For Construction Procurement Management

- Procurement vs. Purchasing

- Steps Involved In The Construction Procurement Process

- Top Construction Procurement Methods

- 6 Ways To Optimize Construction Procurement Management With Software

- Conclusion

As a highly fragmented and complex industry, construction faces manifold challenges, including stagnant productivity, low profit margins, intricate requirements for customized projects, and more. One challenge lies in the construction procurement process, as stakeholders constantly struggle to stay ahead amidst cash flow problems, tight margins, and contract management while ensuring the project’s quality and profitability.

Procurement is an essential part of construction, accounting for up to 70% of a company’s total spending. Still, according to McKinsey’s research, the construction industry’s procurement practices have a low score compared to other sectors like healthcare, travel and transport, and banking and insurance. The reasons include the consequences of COVID-19 and the world’s economic uncertainty, as well as construction companies’ inability to adopt best practices to boost their procurement efforts.

No matter how well you plan and manage your project, procurement mistakes could have a substantial financial impact. However, construction companies that invest time and money in improving their sourcing strategies can generate savings of as much as 12%, as stated by McKinsey, making their companies much more efficient for less money.

If you want to improve your procurement management, using the right digital construction tools and following key best practices is essential. In this blog, we’ll examine construction procurement management and how you can optimize it to boost your success.

Procurement Management in Construction

Procurement in construction is the process of sourcing the products, services, and equipment required to complete a project successfully. The project manager, the procurement team, and other disciplines collaborate to ensure the project’s time and budget are respected.

In other words, procurement is researching and acquiring materials, services, and equipment to meet the project’s needs. This means talking to different contractors and suppliers to ensure they can supply quality services and materials at a price and timeframe that meets project requirements.

That said, it is not just about purchasing. While procurement is a straightforward concept, it can get complicated. It also involves overseeing the logistics of how the different materials will get to the building site and how the services will be integrated into the schedule.

Managing the process is more challenging than simply going to the store and filling your cart with everything you need. Specific procedures must be followed for each service and product that needs to be obtained. In addition, managers will likely deal with multiple vendors at a time, which can be confusing and challenging to manage without the right tools.

During this process, procurement managers need to think about the following:

- the quality of the goods

- their project timeline

- costs

- client requirements, and

- any risk and administration involved with these goods

Some of the common challenges they can face include:

- procurement not connected to other aspects of the project

- procurement avenue selection and supplier management

- cost and time-related issues, e.g., soaring material prices and idling time

- long procurement cycle and material waste

Types Of Procurement In Construction Management

As mentioned above, procurement in construction is about sourcing the required elements to build a project. These elements are divided into three categories that must be managed differently to ensure success. The GC or PM needs to generate a bill of quantities to get all the necessary information to source all these elements.

Materials: The raw materials needed to build the project, including cement, steel, glass, etc. The quality of the raw materials is fundamental to the structure’s success. Therefore, careful research and negotiation are necessary for quality assurance.

Services: This refers to hiring contractors and subcontractors to execute all the required work. An efficient construction bid management strategy is necessary to ensure you hire the best.

Equipment: During a construction project, on-site teams must use different equipment to carry out their work. In the procurement phase, decisions such as purchasing or renting equipment are made, and transportation and delivery dates are discussed to ensure adherence to the project timeline.

Who Is Responsible For Construction Procurement Management

Procurement responsibility will vary depending on the project’s nature, size, and other factors. In most cases, the general contractor (GC) is responsible for sourcing the required materials and specialty services and managing arrival within the expected timeframe. During this process, the GC will hire subcontractors with relationships with trade suppliers who can offer good deals for the project. Therefore, efficient subcontractor management is of utmost importance.

For larger projects, the GC might hire a procurement manager to handle all the details of the procurement process. On the other hand, for smaller projects, it is usually the project manager’s (PM) responsibility to handle it. For extra-large projects, the client might hire an engineering, procurement, and construction contractor (EPC) with a whole team to conduct efficient research and negotiate and acquire materials and services.

That said, procurement is a collaborative effort between multiple project stakeholders, including architects and engineers, who provide expertise to achieve the best results.

Procurement vs. Purchasing

We will not stop and talk about this for too long, but we need to remove some misconceptions to understand the procurement process correctly.

Procurement and purchasing are often used interchangeably in the construction space. However, they differ in that purchasing is just one step in the procurement process; it solely refers to the financial transaction of acquiring materials, services, or equipment from the project. Procurement, on the other hand, is a multi-step process that involves researching, selecting, negotiating, purchasing, managing delivery, and installing, among other things.

Let’s explore each of these steps in detail below.

Steps Involved In The Construction Procurement Process

As mentioned above, project procurement management in construction can involve various steps to secure the goods or services needed for the project. To help you understand the process, we divided the steps into three categories: planning, acquisition, and contract management.

Let’s dive into the construction procurement processes below!

- Planning

The first stage in the construction procurement process is planning. Here, the different stakeholders collaborate to outline the project needs and requirements. The following steps are performed at this stage:

- Define specifications: At this step, the design teams produce drawings and specifications to help define the materials and services needed to complete the project. The design phase is of utmost importance for efficient procurement, as any mistakes or changes in design can affect what needs to be sourced.

- Cost estimation: Once the design is complete, the estimator or cost consultant can begin the cost estimation process. At this step, the team can develop a quantity takeoff to understand the quantities of materials, labor, and equipment required to complete the project and its associated costs. This is where you can start understanding what needs to be procured.

- Define a construction procurement strategy: Once all the previous planning steps are completed. The project manager needs to select a procurement method to approach the sourcing process based on the type of project and available budget. We will discuss these methods in detail later in the post.

- Send out RFP: A request for procurement (RFP) is a document that describes projects and solicits bids. It is sent as the first step directly related to procuring resources.

- Acquisition

The second stage is acquisition. As its name suggests, this is the process of selecting suppliers for materials and services and signing contracts. Some of the steps completed are the following:

- Select a GC: Proposals from contractors are evaluated to decide which best fits the project. In most projects, the general contractor is hired beforehand and handles the acquisition of subcontractors and materials. At this stage, the GC and client agree to the contract terms and can start working on the project. To reduce their own risk, the GC can add a clause to their contract that says the client is responsible for any material cost increases.

- Sign the contract: In most design-bid-build projects, the procurement process can finally begin after the GC is hired, as they are responsible for acquiring materials and specialty services. In most cases, the GC can sign with their trusted supplier, but when it comes to unique, more complex materials, a bidding process might be done to select the best supplier. Suppliers and subcontractors can be chosen based on price, delivery time, availability, materials quality, and expertise. Negotiations about prices, contract terms, delivery schedules, and other contractual obligations are defined here.

- Plan procurement sequence: After the selection is made, the GC can start the procurement schedule. This means planning for the delivery of items and prioritizing the ones with longer lead times needed earlier or at a specific time in the construction site. For instance, the electrical components must be on-site simultaneously with the electrical engineer. This step can start after all items have been approved based on the project design and specifications.

- Send purchase orders (PO): POs are sent after the schedule is approved. Once the supplier receives the PO, they can start fabricating or shipping materials and equipment to be sent at the agreed time.

- Contract Management

The third and last stage in the process is contract management, which, as its name suggests, involves all tasks related to ensuring the contracts are carried out accordingly and managing any issues that arise.

- Procurement monitoring: Now that the contract is in place and the suppliers have a clear plan, the GC, PM, or procurement manager needs to monitor and manage the entire process throughout the construction project. This can involve checking the quality of each procurement, monitoring the timeline, and ensuring that everything is up to date with compliance. Any changes in the scope of work or quantity of materials are also managed at this stage.

- Closing the contract: At the end of the construction project, before closing the contract, final inspections are carried out to ensure everything was built or installed according to the contract and project specifications. This is often checked by the design team, project owner, and regulatory entities in collaboration with the person in charge of procurement.

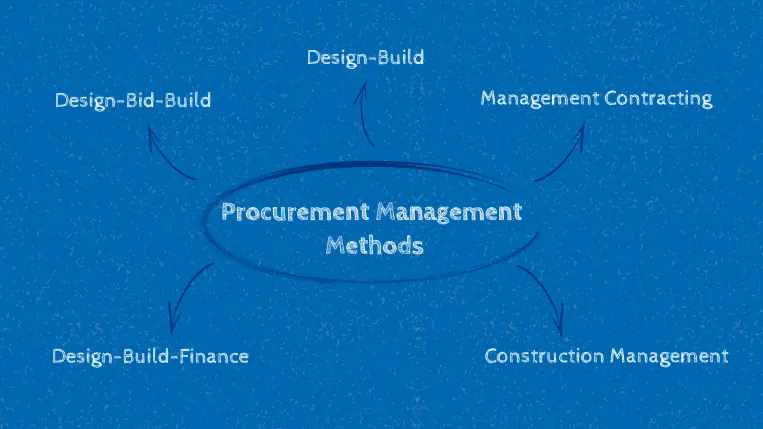

Top Construction Procurement Methods

We’ve discussed construction procurement management, what the process entails, and who is responsible for it. Now, just like in many other construction-related processes, there are different methods you can use to carry out your procurement process. Below, we discuss the main ones.

- Design-Bid-Build

This is the most common or traditional method, and, as its name suggests, it is divided into three phases. It starts with the design phase, where the client hires a design team of architects and engineers to create the project outline, design, and specification documents. Then, the project is put out to bid, and a general contractor is hired, who will oversee hiring and managing subcontractors to complete the work—the GC also oversees the final build stage within the agreed timeline and budget.

The advantages of this method are that careful preconstruction planning reduces the risk of overspending, delays, or design mistakes. Plus, a competitive construction bidding process can help lower costs that can be allocated to other areas of the project.

Disadvantages include potential communication issues between parties involved because the design is done before the GC is hired, so it misses their input. This method is also unsuitable for fast-track projects as rushes can cause delays or overspending.

In this procurement method, the client hires a general contractor (GC) or a team of professionals to oversee the design and building stages of the project. Since the GC is responsible for the project’s design, acquisition, and management, the work becomes much more risky for them. Therefore, careful planning and risk assessment are necessary to avoid major issues.

Some of the most significant advantages of this method include better communication and decision-making, as there is just one single party responsible, and the potential for faster project completion as design and construction are done together.

Disadvantages can include limited owner control over the design process, making the project more expensive.

In this method, the client hires a management contractor and a design team to collaborate on the project’s design during the planning phase. The management contractor is paid an additional fee for managing construction work later, but they usually hire a project team or subcontractors to complete that part. The management contractor is responsible for ensuring all subcontractors carry out their work within the time agreed in their contracts.

This method’s recognized advantages include faster and more accurate design and construction work due to the contractor’s early involvement in the design stage, which can help identify potential issues early on and optimize the design.

Potential disadvantages of the method include the complexity of managing multiple subcontractors and communicating with them to track project progress.

A similar method called construction management is also valuable for clients with more experience. This method differs from management contracting because the client directly hires multiple contractors and uses the management contractor as a consultant. This method involves more client involvement, so it is recommended for more experienced companies.

A big downfall of this method is that if a contractor is late with their part of the work, it can delay the upcoming works that need to be completed by other contractors, delaying the entire project.

Finally, in this procurement method, the client awards a single contract for the project’s design, construction, and financing. There are two ways this can go. The client can tell the contractor to spend only a fixed amount on the project, and any additional costs need to be covered by them, or the contractor can finance the project entirely and then lease it to the client for a period.

This is a great method for clients who need to build a project quickly but don’t have the capital to do it. It also provides a high level of cost certainty. The disadvantage could come from the contractor as they have all the responsibility and risk associated with the project.

6 Ways To Optimize Construction Procurement Management With Software

Clearly, project procurement management in construction can be a complicated process. To optimize it and achieve success, you need to use fit-for-purpose construction procurement software that allows you to quickly gather and understand your project’s data to develop data-driven answers in real-time.

This makes monitoring suppliers and contractors far easier for procurement management. You get a detailed overview of your available materials and services, which leads to better project management and control.

Below, we’ll discuss six ways such software can help you manage procurement.

1. Automatically generate procurement schedule

Say goodbye to manually creating procurement schedules on spreadsheets. A professional construction platform, like RIB 4.0, integrates all processes and their data along the building project lifecycle. Based on the pre-defined events and the material list, the platform will automatically generate a procurement schedule and integrate it into the main construction schedule. With both schedules synchronized in one database, the project’s on-schedule progression becomes much easier, minimizing idle time.

2. Visualize your procurement plan in 3 dimensions at the preconstruction phase

Professional construction tools integrate the 3D BIM model with time factor (4D) and cost information (5D), allowing for a 5D BIM project lifecycle simulation in the preconstruction stage. This enables procurement requirements to be generated directly from the 5D model, catalog, or cost estimate in the planning stage, creating a clear and optimized plan before the physical construction even starts. Not only is data accuracy ensured, but the savings in time and labor can be immense.

3. Comparing all dimensions to work with the best partner

After a requisition is created and approved internally, the platform you decide to invest in should allow you to send out the Request for Quote (RfQ) to invite vendors to submit their bids. All quotes will be automatically compared, providing an apples-to-apples approach to evaluating quotes and supporting your decision-making. Price and supplier track record are assessed as the basis for selecting the best supply partner for materials and services.

4. Comprehensive evaluation of your business partners for improved collaboration

Every business partner’s collaboration history, including projects, contracts, and execution performance, along with all their branches, contact details, and partner networks, is stored in one place for critical decision-making. Partner evaluation reports can be created based on customized evaluation criteria for future project reference.

5. Integrated with all the other up- and- downstream processes

Since the construction lifecycle is connected by data, professional construction procurement software, such as RIB BuildSmart, should allow you to integrate your procurement data with all upstream and downstream processes, such as estimate, bidding, tendering, and project timeline, truly aligning all departments to work together more efficiently. Connecting all project stakeholders in a centralized location can significantly enhance collaboration and construction productivity.

6. Invoice tracking in an easy yet smart way

An invoice module allows you to record invoice documents from all business partners. After reconciliation, this information will be synchronized to your finance system by connecting your construction platform with existing tools, seamlessly connecting building project management and enterprise resource platforms for lean account management.

Conclusion

Regardless of the scale of your construction project, procurement is one of the most vital processes for its success. Careful management is essential for an organized project and an excellent bottom line.

Investing in the right construction procurement software to manage your procurement process can make a significant difference. These solutions offer a centralized environment to manage all project aspects, ensuring a collaborative and informed project from start to finish. Are you ready to start? Get your free product demo!

Most Recent

16 mins read

16 mins read

16 mins read

22 mins read

Ebook